CNC metal machining (Computer Numerical Control) is an indispensable part of modern manufacturing. It achieves efficient, high-standard processing and fabrication of metal materials through computer numerical control technology. This technology enhances production efficiency, reduces manufacturing costs, and improves product precision. Whether in aerospace, automotive manufacturing, or medical equipment industries, CNC metal machining plays a vital role.The following content will briefly describe the CNC Metal Machining Guide

What is CNC Metal Machining?

CNC metal machining is the process of precision-processing metal materials using computer numerical control technology. Through programmed instructions, it controls the movement trajectories and processing parameters of machine tools, enabling the formation of complex geometric shapes on metal surfaces. Compared to traditional manual machining, CNC processing is more precise, faster, and capable of efficiently producing large volumes of parts.

Primary Materials for CNC Metal Machining

Different materials exhibit distinct physical properties and machining requirements. Below are several common materials used in CNC metal machining:

Aluminum Alloy

Aluminum alloys are widely used in aerospace, automotive, and electronics industries due to their lightweight nature, excellent mechanical properties, and corrosion resistance. They offer superior machinability, making them suitable for CNC milling, turning, and other operations. The material is relatively easy to cut, making it ideal for high-volume production.

Stainless Steel

Stainless steel offers outstanding corrosion resistance and strength, making it ideal for manufacturing high-strength, durable components. Although challenging to machine, CNC technology enables efficient, high-precision processing of stainless steel parts. It is widely used in medical equipment, food processing machinery, and similar fields.

Titanium Alloys

Titanium alloys, prized for their superior strength-to-weight ratio, high-temperature resistance, and corrosion resistance, are frequently used in aerospace, military industries, and medical device components. Due to their high cost, hardness, and machining difficulty, they demand CNC equipment with high precision and technical capabilities.

Copper Alloys

Copper alloys, valued for their excellent electrical conductivity and corrosion resistance, are widely used in electrical, electronic, and telecommunications fields. CNC machining of copper alloys is relatively straightforward, enabling efficient and precise production of complex-shaped components.

Steel

Steel materials are extensively used in industry, particularly carbon steel, alloy steel, and tool steel. Machining steel presents challenges, especially with high-hardness grades. However, continuous advancements in modern CNC technology have significantly enhanced the machining precision and production efficiency of steel components.

Cast Iron

Cast iron is extensively used in mechanical foundations and engine components due to its excellent casting properties and superior vibration damping. Although relatively hard, its outstanding machinability makes it a commonly used material in CNC machining.

Advantages of CNC Metal Machining

High Precision and Repeatability

CNC metal machining achieves exceptional processing accuracy (micron-level), ensuring flawless results even for intricate and delicate components. Since every step of the tool path execution is computer-controlled, each machined part maintains consistent standards, significantly reducing human error’s impact on quality.

High Production Efficiency

CNC technology automates the machining process, reducing manual intervention and enabling the production of more parts in less time. Compared to manual milling and grinding using traditional lathes, CNC machines offer significantly higher efficiency—a particularly attractive feature for businesses requiring mass production.

High Flexibility

By adjusting programs and tool sizes, CNC metalworking easily adapts to processing parts of varying dimensions, shapes, and locations. A single machine can perform multiple operations—milling, turning, drilling, grinding—significantly enhancing processing flexibility.

Material Savings

CNC machining minimizes material waste through high-precision control. Compared to traditional methods, CNC technology optimizes cutting paths and reduces scrap, improving material utilization.

Applications of CNC Metal Machining

Aerospace

In aerospace, precision components are critical for safety and reliability. CNC metal machining efficiently produces complex-shaped metal parts (surfaces, cavities) with high precision and strength, meeting aerospace demands.

Automotive Manufacturing

Modern automotive manufacturing also demands high precision and strength in components. CNC metal machining enables more efficient and accurate production of automotive parts (engines, gears, bearings, bushings, rubber seals), ensuring vehicle quality and performance.

Medical Devices

The manufacturing of medical devices demands not only high precision but also smooth, flawless surfaces. The application of CNC metalworking technology in this field ensures every medical device component meets stringent quality requirements.

Mold Manufacturing

CNC technology finds particularly extensive application in mold manufacturing. Since molds endure prolonged exposure to high temperatures and pressures, CNC metal machining produces molds with exceptional precision and overall durability.

Technological Trends in CNC Metal Machining

Intelligence and Automation

With advancements in artificial intelligence and big data technologies, CNC metal machining is evolving toward intelligent operation. Through machine learning and data analysis, CNC systems can self-optimize machining processes, enhancing production efficiency and reducing failure rates.

Composite Material Processing

With the widespread adoption of new composite materials in aerospace and other sectors, CNC metal machining technology is expanding into composite material processing. The unique properties of composites demand greater precision in machining, placing higher demands on CNC capabilities.

Integration of Additive Manufacturing and CNC

The combination of additive manufacturing (plastic/metal 3D printing) and CNC machining is emerging as a new trend. Additive manufacturing creates complex geometries, while CNC machining enables subsequent precision finishing of these shapes. This synergy further enhances production efficiency and flexibility.

How to Select Suitable CNC Metal Machining Services

When selecting a CNC metal machining service provider, beyond price considerations, prioritize the following aspects:

Technical Capabilities

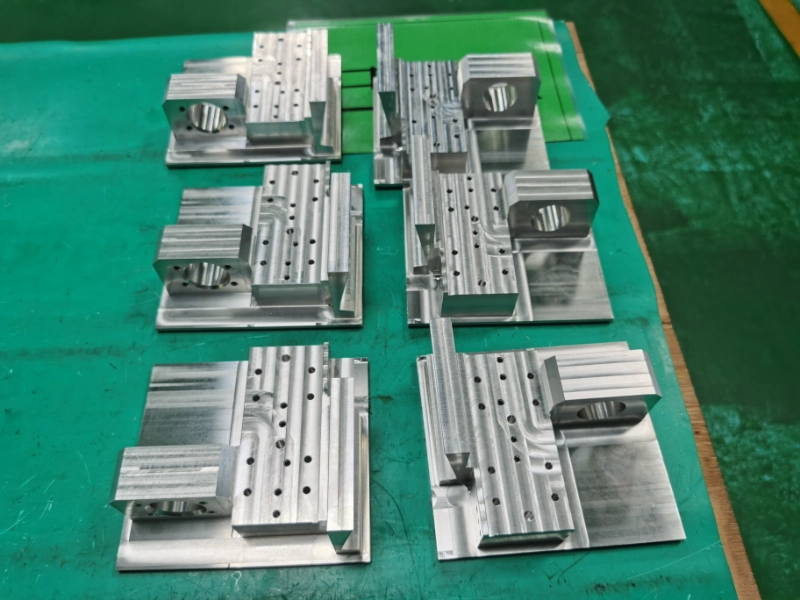

Assess whether the provider possesses advanced CNC equipment and a highly skilled technical team capable of handling complex machining demands. This is a key indicator of reliability. Evaluate by reviewing comprehensive images of their CNC machining center, worker attire, and the variety and quantity of machinery.

Machining Precision

Different projects demand varying levels of precision. Confirm whether the provider can meet your required accuracy standards. Additionally, assess whether the CNC service provider can optimize precision requirements based on your specific circumstances and machining experience, thereby reducing processing costs.

Customer Feedback and Case Studies

Reviewing client testimonials and successful case studies helps gauge the provider’s industry reputation and credibility. Assess their standing by examining photos and videos of their CNC prototype showroom, quality control facilities, and equipment personnel.

Delivery Lead Times and Service Assurance

Timely delivery is a critical component in modern manufacturing. Ensuring service providers deliver products on schedule with consistent quality and quantity, while offering prompt and reliable after-sales support, accelerates new product launches and facilitates subsequent part optimization and refinement.

Summary of CNC Metal Machining Guide

CNC metal machining has become an indispensable core technology in modern manufacturing. Whether enhancing production efficiency, guaranteeing machining precision, or meeting diverse industry demands, CNC technology demonstrates significant advantages. With continuous technological advancements, CNC metal machining will expand into more fields, propelling manufacturing toward greater intelligence and efficiency. If you have projects or plans requiring metal CNC machining, feel free to contact Weldo‘s professional customer service team anytime for prompt consultation and quotes.