CNC precision machining parts are essential components in industries that demand tight tolerances, high dimensional accuracy, and consistent performance. From aerospace and medical devices to electronics and automation systems, cnc machining parts play a critical role in ensuring reliability, safety, and functionality. This guide explains what defines precision machining, how it differs from standard CNC machining, cost considerations, and how to choose the right supplier.

What Are CNC Precision Machining Parts

CNC precision machining parts are components manufactured using computer numerical control (CNC) equipment with strict control over tolerances, surface finish, and dimensional repeatability. Compared with general machining, cnc machining parts are produced under tighter process control and higher inspection standards.

Key characteristics include:

- Tight tolerance control

- High dimensional accuracy

- Stable repeatability across batches

- Strict quality and inspection requirements

CNC precision machining parts are typically used where even minor deviations can affect product performance or safety.

CNC Precision Machining vs Standard CNC Machining

Understanding the difference between precision and conventional machining helps buyers set realistic expectations.

Standard CNC Machining

Standard CNC machining focuses on functional dimensions with relatively wider tolerances. It is suitable for structural parts, housings, and components where extreme accuracy is not required.

Typical features:

- Tolerances around ±0.05–0.10 mm

- Basic inspection requirements

- Lower machining and inspection cost

CNC Precision Machining Parts

CNC machining parts require enhanced process control and tighter tolerances.

Typical features:

- Tolerances of ±0.01 mm or tighter

- Advanced inspection and measurement

- Higher machine accuracy and stability

The difference lies not only in tolerance but also in consistency, inspection depth, and process capability.

Precision Machining Requirements and Standards

Producing cnc precision machining parts requires more than accurate machines.

Key requirements include:

- Stable machine platforms with thermal control

- High-quality cutting tools and fixturing

- Process planning and toolpath optimization

- Controlled machining environments

Precision machining is a system-level capability rather than a single process.

Tolerance Grades and Accuracy Levels

Tolerance is one of the most critical factors for cnc machining parts.

Common Tolerance Ranges

- ±0.05 mm: General functional components

- ±0.02 mm: High-precision mechanical parts

- ±0.01 mm or tighter: Critical precision components

Achieving tighter tolerances increases machining time, inspection effort, and cost.

Dimensional Accuracy and Repeatability

For cnc precision machining parts, repeatability across multiple batches is as important as single-part accuracy. Consistent process control ensures that parts perform reliably over time.

Common CNC Precision Machining Parts and Applications

CNC machining parts are used across multiple high-end industries.

Typical Precision Machined Components

- Shafts, pins, and bushings

- Precision housings and enclosures

- Mounting bases and brackets

- Valve components and manifolds

- Precision plates and frames

These parts often require controlled geometry, surface finish, and dimensional stability.

Application Industries

CNC precision machining parts are widely used in:

- Aerospace and aviation

- Medical devices and instruments

- Semiconductor and electronics equipment

- Industrial automation and robotics

- Optical and measurement systems

Each industry applies different standards but shares similar precision requirements.

Materials Used for CNC Precision Machining Parts

Material selection directly affects machinability, accuracy, and cost.

Common Precision Machining Materials

- Aluminum alloys (6061, 7075) – lightweight, stable, cost-effective

- Stainless steel (304, 316, 17-4PH) – strength and corrosion resistance

- Carbon and alloy steels – mechanical strength and wear resistance

- Brass and copper alloys – excellent machinability and conductivity

These materials are commonly used for standard cnc precision machining parts.

Special and Advanced Materials

For demanding applications, cnc precision machining parts may use:

- Titanium alloys – aerospace and medical use

- Inconel and superalloys – high-temperature environments

- PEEK and PTFE – chemical resistance and insulation

These materials increase machining complexity and cost but provide superior performance.

Surface Finishing Options for Precision Machining Parts

Surface finish affects functionality, durability, and appearance.

Common Surface Treatments

- Anodizing – corrosion resistance and surface hardness

- Passivation – stainless steel corrosion protection

- Electropolishing – smoothness and cleanliness

- Plating (nickel, chrome) – wear and corrosion resistance

- Precision polishing – improved surface roughness

Surface finishing is often a critical step for cnc machining parts used in regulated industries.

CNC Precision Machining Parts Cost Range

Cost depends on tolerance, material, complexity, and volume.

Typical Price Ranges

- Simple precision parts: USD 50–150 per piece

- Medium complexity precision parts: USD 150–400 per piece

- High-precision or complex parts: USD 400–1,200+ per piece

Inspection and setup often represent a significant portion of total cost.

Factors Affecting Precision Machining Cost

Major cost drivers include:

- Tolerance and accuracy requirements

- Part geometry and feature density

- Material type and machinability

- Surface finish and post-processing

- Order quantity and repeatability

Understanding these factors helps buyers evaluate quotations more accurately.

How to Choose a CNC Precision Machining Parts Supplier

Selecting the right supplier is critical for long-term success.

Key evaluation criteria:

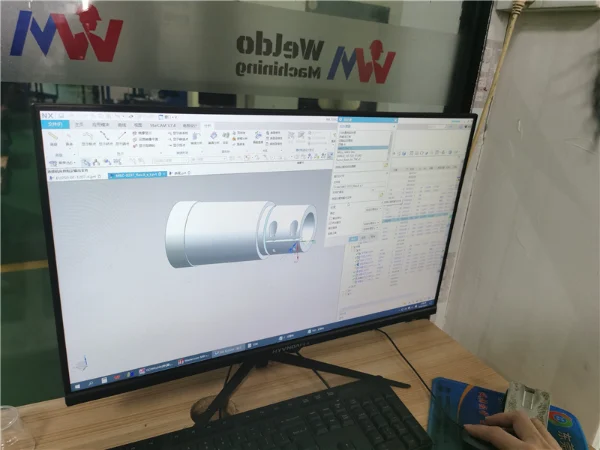

- Proven experience with cnc precision machining parts

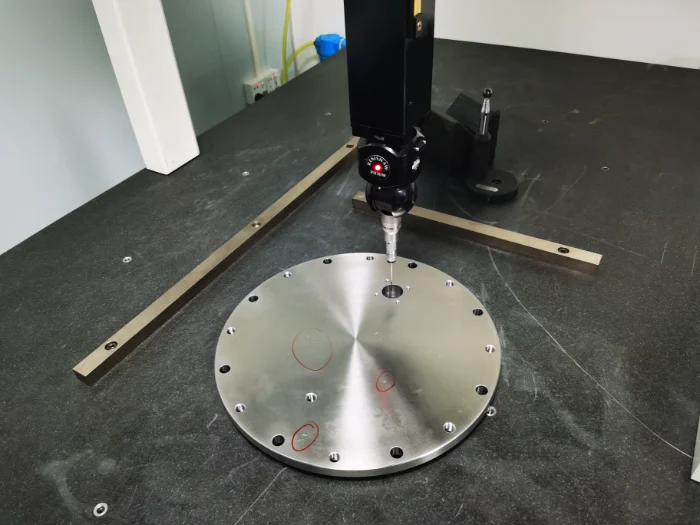

- Advanced inspection and measurement capability

- Material traceability and documentation

- Engineering and DFM support

- Stable quality and delivery performance

A qualified supplier reduces risk and ensures consistent results.

Quality Control and Inspection Capability

Professional suppliers of cnc precision machining parts should offer:

- CMM inspection

- In-process measurement

- First article inspection (FAI)

- Detailed inspection reports

Inspection capability is as important as machining equipment.

Final Thoughts on CNC Precision Machining Parts

CNC precision machining parts require strict control over accuracy, tolerances, materials, and inspection processes. By understanding the differences between standard and precision machining, evaluating cost drivers, and selecting the right supplier, buyers can achieve consistent quality and long-term reliability.

If you are sourcing high-quality cnc machining parts with tight tolerances, advanced materials, and stable quality control, Weldo Machining provides professional precision CNC machining services tailored to demanding applications. Contact Weldo Machining today to discuss your project requirements and receive a detailed quotation.